Some Known Details About Concrete Coating

Wiki Article

Things about Commercial Flooring

Table of ContentsSome Ideas on Fort Mill Epoxy You Need To KnowThe Greatest Guide To Concrete RepairThe Definitive Guide for Fort Mill EpoxyIndicators on Granite Garage Floors You Need To Know

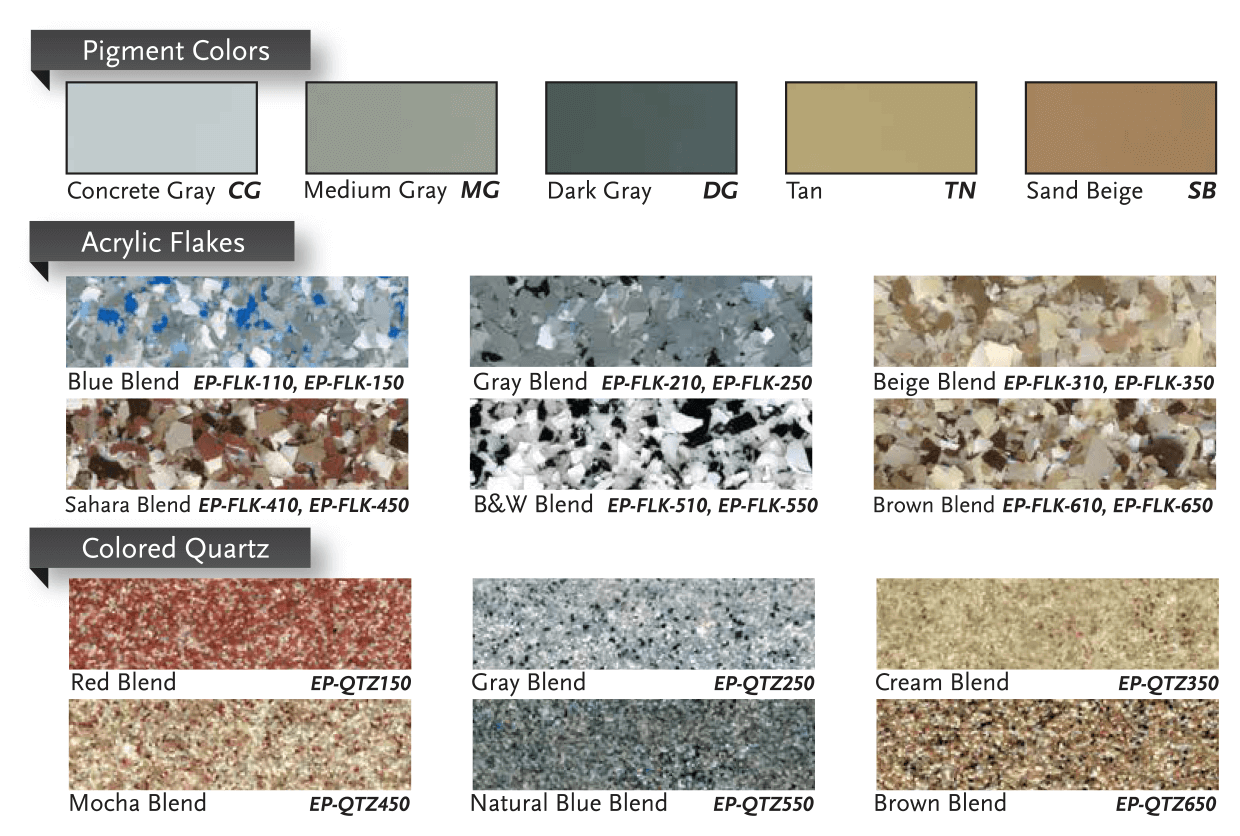

Time: 05:51 Discover out what items are great to use as an attractive garage floor surface area. A concrete coating is a flooring covering for cellars, garages, storage facilities, producing plants, dining establishments, stores and more. An excellent finishing provides concrete a durable layer of defense against heavy traffic, abrasion, chemicals, as well as moisture direct exposure.Layer Types Epoxies Polyaspartics Special-Effects Covering Details The choice of products today for finish concrete has actually never ever been better, as producers strive to meet market demands for more recent formulas that are much faster curing, even more abrasion immune, lower in harmful VOCs as well as stick better to correctly ready surfaces. And also numerous of today's finishing items are readily available with an abundance of ornamental alternatives, including a wide selection of mix-in pigments as well as other add-ins for achieving unique visual results.

The variety of choices is overwhelming, as well as each item will vary-- a minimum of somewhat-- in regards to performance, ease of application, economic climate as well as look (Carolina epoxy). The obstacle is to discover one of the most economical and sensible solution amongst the lots of items on the rack. It would be impossible to compare every concrete finish on the market, because there are literally hundreds to pick from.

These offerings generally set you back even more than their typical equivalents, but can be a lot more budget friendly in the lengthy run by saving installment time, enabling floors to be returned right into service sooner and also lasting much longer. Some products additionally achieve special decorative effects, such as metal or luminous finishes. 100% solids epoxy covering with a urethane leading coat.

The 8-Second Trick For Concrete Repair

For the objectives of this guide, we're narrowing down the meaning to refer just to noncementitious polymer items generally applied at densities of less than 1/16 inch. (Click on these web links for suggestions on acquiring and also making use of cement-based garnishes and also overlays as well as epoxy-aggregate systems.) Without obtaining too scientific, a polymer is generally a chemical compound or mixture of compounds.

As a result of the chemical nature of polymer layers, producers will certainly often tinker with the properties and molecular makeup of their products to improve their performance as well as offer other advantages, such as faster curing times or lower VOCs. When contrasting the features of various products, the very first step is to check out the coating suppliers' information sheets and also technological requirements.

Several specialists like epoxies due to the fact that they create a durable high-gloss coating with premium solidity and also abrasion resistance. Nevertheless, in spite of their protective benefits, conventional epoxies have some disadvantages that can restrict their use on particular tasks, such as: Long concrete healing times prior to application (usually a minimum of 30 days) Loss of adhesion in the visibility of moisture The tendency to yellow when exposed to ultraviolet light Most traditional epoxies also are two-component systems that call for mixing at the proper proportion right prior to usage - Concrete repair.

An Unbiased View of Granite Garage Floors

DRYLOK Concrete Protector. United Gilsonite Laboratories in Scranton, Several producers now offer one-part ready-to-use epoxies that need no blending before application. These user-friendly epoxies poured concrete floor are said to contrast in efficiency to two-part systems and are appropriate for both household as well as additional reading commercial applications, consisting of garage floorings, driveways, basements, industrial showrooms, gas stations and also dining establishments.They additionally are UV-stable and also will not yellow or chalk when related to exterior pieces. Dampness vapor transmission via polyacrylate terrazzo joints. Trick Resin Business in Batavia, OH A lot of epoxy flooring finishings are impenetrable to dampness as well as can stop working if put on damp substrates or to slabs with high moisture-vapor exhaust rates (see What Troubles Does Moisture Produce?).

Some will certainly even bond to damp substratums and to new concrete pieces after only 4 or 5 days of healing, making it excellent for fast-track projects. Numerous epoxies need a minimal drying out time of 24 hours prior to they can be recoated (depending on application temperatures and humidity conditions) and need to treat for numerous days prior to they can approve traffic.

Keep in mind: All of these new epoxies are water-based as well as reduced in VOCs as well as odor. They also are available in pigmented coatings or can be tinted. Advantage Chemical Coatings. Insta, Drive finish, a self-priming system. Kamcrete in Mesa, AZ Polyaspartics (a kind of polyurea) are the newest layer items to hit the market, and they are getting lightweight aggregate in appeal due to their super-fast setup times.

Epoxy Floor Things To Know Before You Buy

Polyureas have been available readily since the 1980s, polyaspartics are a much more current innovation with boosted efficiency attributes and also much easier installation (see What Are Polyaspartics?). Granite garage floors. Beyond the benefit of permitting projects to be finished in document time, these flooring finishings supply numerous other benefits, consisting of: The capacity to be applied to full thickness in one coat Greater abrasion as well as influence resistance than epoxy or urethane finishes The capacity to be used at high or low temperature levels Outstanding bonding features and also UV stability They appropriate for both residential and also industrial applications and also are especially popular for garage floorings, driveways, retail facilities, automobile showrooms, stockrooms as well as various other slabs based on hefty wear and tear.When you aspect in the reduced labor prices and downtime, the additional expense can typically be warranted. Below is a tasting of some of the products offered. Many of these are marketed as full attractive flooring systems that can be tinted onsite throughout mixing and also embellished with decorative vinyl chips or quartz grains in a broad range of color combinations.

Functional Structure Products in Carson, CA Moon Decorative Concrete One-Day Floors: A three-coat attractive flooring system for garage pieces, patio areas, walkways, driveways and swimming pool decks. It is claimed to have exceptional penetration and also bond strength to appropriately ready surface areas and also is immune to hot-tire marks, commercial and home cleansers and also swimming pool therapy chemicals.

Report this wiki page